Have you ever wondered how complex metal shapes are created? The answer lies in the world of metal stamping. Here at US Machine & Tool, we have been offering this as one of our services since our founding. An instrumental part of us delivering quality products to our customers has been our Plant Manager, Mike Alvis. Over 32 years of experience has led Alvis to a detailed knowledge of metal stamping. We spoke to Alvis to share the ins and outs of the process and how it can be used.

What is Metal Stamping?

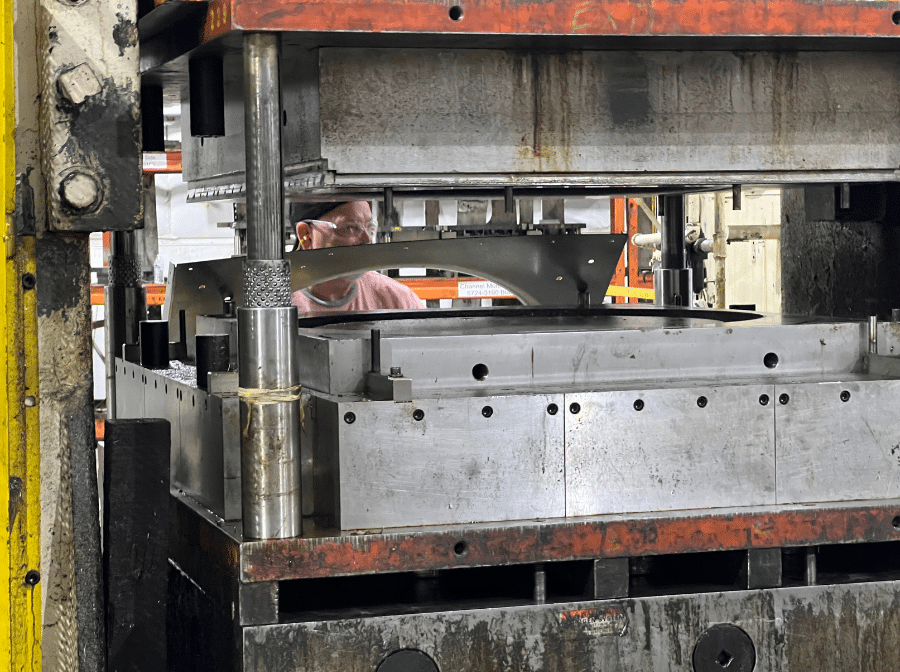

Metal stamping is the process of stamping metal to create a net shape using a stamping press or a die. This can be done in a number of ways, depending on a customer’s needs and the complexity of the part, as the complexity of the part will determine the number of tools needed.

Progressive Die Stamping

When a high volume of parts is needed, typically anything over 50K to 100K or more per year, progressive tooling is used. Progressive stamping uses a coil stock material, which can be made of numerous alloys. The process is made up of stations that the metal runs through to ultimately produce a finished part made to the customer’s specifications. The number of stations on a progressive tool is determined by the intended finished part design.

Deep-Drawn

Because metal can be used in a variety of applications, deep-drawn stamping is used to stamp a cup shape into the metal. This method requires an alloy that is designed and produced to meet the draw characteristics. Having the appropriate alloy is the key to achieving the desired shape. Similar to progressive die stamping, the metal goes through stations to gradually work the metal to the desired shape.

Metal stamping has a wide range of applications and because of this, US Machine & Tool has been able to help a number of industries, including HVAC, lawn and garden products, the metal building industry, and even custom furniture manufacturing.

With US Machine & Tool’s long history and Alvis’s 32 years of experience, it is no surprise that we have had our fair share of challenging metal stamping projects! Alvis shares, ”One of the more challenging stamped parts that I have been involved in was building a metal stamping tool that manufactured a metal chair leg component. As volumes increased over the years of producing this product, we needed to build another tool that produced the same part but two parts with each stroke of the press instead of one in order to meet our customer’s demand and help control the overall cost of the component.”

No matter the industry and its unique needs, US Machine & Tool is committed to helping you create custom metal parts for any project.